Here are a few pictures of a house under construction near Jacksonville, Florida. The siding is Hardiplank®, a bevel lap fiber-cement board material that has become a very popular alternative to wood, vinyl, or aluminum. It is composed of portland cement, ground sand, cellulose fiber, “select additives” and water. However, this pet peeve is not about the material used to cover the exterior walls of this new house. Rather, what bothers me about this particular siding installation is the shortcut that was taken by the “mechanics” that have improperly installed it.

From a distance, the problem with this installation is not readily visible. In fact, at first glance the average person might not notice that something was done wrong. The siding will not fall off, or leak, or create any other adverse affects on the house because of the way it was installed. Additionally, even if the homeowner did notice what was done wrong, they would probably have a very difficult time making the “carpenters” that installed the siding correct the problem. The siding crew would most likely tell the owners that they had installed the siding “in accordance with the manufacturers written installation instructions”, and from what I have been able to determine, they would be correct. At the time of this writing, I was unable to find any mention in the installation instructions for this particular product that dealt with what had been done improperly. Yet, by ignoring “standard practices and procedures” for installing bevel lap siding products, a less than ideal situation was created that will be visible for as long as this siding remains on this house.

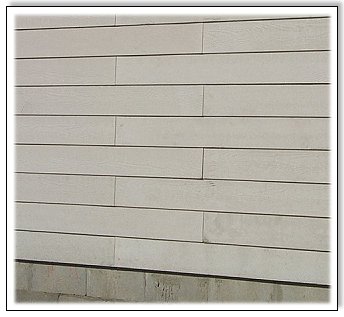

In the enlarged picture on the left, you should be able to see the problem that I have with this siding installation. The butt joints have been located right in the middle of the wall and staggered every other board. This creates what I call a zipper effect, which extends the full height of the wall and visually splits the area into two sections with an unattractive seam up the middle.

While most natural wood products are sold in random lengths, most manufactured siding comes in a standard length for that particular product based upon weight, ease of shipping and installation concerns. This type of Hardiplank siding is manufactured in 12 foot lengths. The wall on this house happens to be 22 feet long. The siding crew started at one corner of the house and installed one full length of siding. Then they cut a 10 foot piece of siding to complete the first row. For each successive course of siding, they used the same two lengths and simply alternated 10 and 12 foot pieces up to the top of the wall.

As any knowledgeable carpenter knows, butt joints should be made over a stud and separated horizontally by at least a foot, and preferably more. That was done in this case, but it has also been common practice for hundreds of years to avoid stacking butt joints for at least 3 courses. With some siding materials, like cedar shakes, this is done to keep water from easily getting behind the siding. With others, it is simply good common sense practice, which results in less attention being drawn to the joints between one piece of siding and the next.

Unfortunately, this siding crew either didn’t know that there was a better way to install siding, or they did but chose a speedy installation over an aesthetically appealing one. In my opinion, this particular wall would have looked much better if someone had simply taken a few extra minutes to consider the final appearance of the siding before it was installed. Had the butt joints been spaced further apart and not repeated every other course, the zipper effect would not have appeared and the 2 foot piece of siding that was thrown away for each course on this side of the house would not have been wasted.

If the zipper effect bothers you as much as it does me, you should be able to avoid this situation on your house by bringing it to the attention of your siding installers before they start their work. Oh, by the way, don’t take too much time explaining this pet peeve to your siding crew because another fast working subcontractor just arrived on the job site to install your 12 foot pieces of hand-picked, clear, all heart, redwood decking for your 22 foot wide custom deck;-)

Good luck with your project, thank you for visiting B4UBUILD.COM and have fun building!

Take care,

Greg